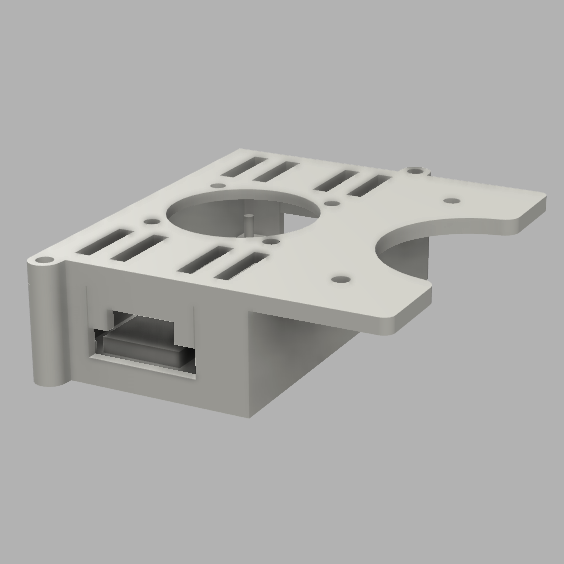

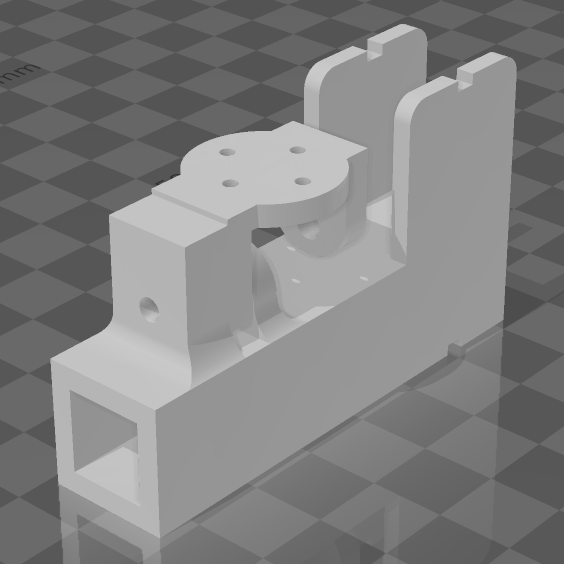

3D PRINTING SERVICES

We offer a range of 3D printing services to meet your needs, including rapid prototyping, on-demand manufacturing and recreating or improving discontinued parts or products. So, whether you want to a one-off prototype, or order multiple parts, reach out and we will find the best option for you.

How can you bring your product to life?

Send us your 3D file or come to us with a design for one-off prints or batch production runs. Whether you need rapid prototyping, on-demand manufacturing, to recreate a discontinued part or product or anything else, we can do it for you.

We have listed some simple steps below to show how the process can work:

1. Create your 3D file

Work with our design engineers, we can help you design or replicate your product, creating a 3D model which can be printed out on our one of our 3D printers.

2. Select your material

FDM uses thermoplastic materials. The most common filament materials for FDM printing include:

- PLA+ (Polylactic Acid)

- ABS (Acrylonitrile Butadiene Styrene)

- PETG (Polyethylene Terephthalate Glycol)

- Nylon

- TPU (Thermoplastic Polyurethane)

3. Begin the printing process

Our printers will use your 3D model to create your product:

- The printer heats the filament to its melting point and extrudes it through a heated nozzle.

- The nozzle moves along the X, Y, and Z axes, depositing the molten filament in layers, one on top of the other.

- As each layer is deposited, it cools and hardens, fusing with the layer below it.

- The object is built layer by layer from the bottom up.

- Each layer bonds to the one below it, and the process repeats until the object is complete.

4. Final checks

After printing, the object may require post-processing, like removing supports or sanding.

Ready to get started? Email Forty3d.24@gmail.com or call 07927656878 for a free quote.

What material should you choose for your 3D printed products?

We offer a range of fused deposition modelling (FDM) 3D printer materials to suit your needs, including:

PLA+

PLA+ is known for being strong and impact-resistant, making it a good choice for those printing functional parts that require a bit more durability.

Due to its improved strength, PLA+ is often used for creating functional prototypes, mechanical parts, and tools across a range of industries, including mechanical, electronics, food and medical. It's ideal for products that need to hold up under regular use, such as brackets, clips, or small mechanical components.

PETG

PETG is more a flexible plastic, allowing it to withstand more bending and impact. This makes it a good choice for parts that need to withstand mechanical stress. Alongside this, PETG is resistant to many chemicals, is considered food-safe when used appropriately, and offers good resistance to environmental factors like UV rays and moisture.

Because of these properties, PETG is used in a wide range of products, including mechanical parts and prototypes to packaging, medical devices, and even in the food and beverage industry.

ASA

ASA is a thermoplastic polymer used for products that require a material with high strength, durability, and resistance to environmental conditions such as UV, heat and weather resistance.

This makes it great for use in the automotive industry, including grills, trims and housing for cars exposed to elements. Alongside this, this material is suitable for outdoor applications such as garden tools, weather-resistant enclosures and consumer goods such as protective cases for electronics and equipment.

ABS

ABS is valued for its toughness, impact resistance, and versatility in 3D printing, making it ideal for a wide range of functional, durable, and customisable parts. It can also be easily sanded, drilled, and painted, making it ideal for creating functional prototypes that need to undergo testing or further refinement. ABS also has a higher heat resistance than other materials.

Because of these qualities, ABS is commonly used for rapid prototyping, mechanical components, automotive parts, electrical enclosures, toys and household products, kitchen appliances, custom tooling and electrical insulation.

What is fused deposition modelling (FDM) 3D printing?

FDM is one of the most popular and widely used types of 3D printing technologies. It melts and places a selected product layer by layer to create a product, based on a digital model.

There are many benefits to FDM printing, including the many types of materials that can be used for a variety of products. Because of this, FDM 3D printing is widely used for:

- Prototyping (rapid prototyping for design validation)

- End-use parts in industries such as automotive, aerospace, and consumer products

- Custom tools and fixtures

- Hobbyist projects (for things like miniatures, models, or creative art)

Contact us

We can advise you about the best material for your project, so reach out now.

Email us: Forty3d.24@gmail.com

Call us: 07927656878